About Us

INXDOLHOM

Our Company

Jiahong Creative is an OEM/ODM manufacturer in China,specializing in custom PVC figurines and IP-authorized small appliances.

We offer one-stop solutions from design and prototyping to mass production, supported by in-house manufacturing and strict quality control.

meet OUR team

A multidisciplinary in-house team covering design, engineering, costing, and sales — ensuring smooth execution from concept to mass production.

2D design team

Transforms customer ideas and references into clear 2D drawings, defining appearance, proportions, and key visual details.

3D design team

Builds accurate 3D structures based on 2D designs, optimizing product structure for tooling and mass production.

Software Engineer Team

Develops and customizes embedded software to meet functional requirements, user interaction, and system stability needs.

hardware Engineer Team

Designs and validates electronic hardware solutions, ensuring performance, safety, and manufacturability.

Product Pricing Analyst

Evaluates material, tooling, and production costs to deliver accurate, transparent, and competitive pricing.

Sales Team

Connects customers with our factory teams, managing communication, timelines, and project execution from inquiry to delivery.

Our Factory

Our factory spans over 30,000㎡ with 700+ employees, providing full OEM/ODM manufacturing from mold making to final assembly.

We support licensed and custom products for global brands with stable quality and efficient production.

An OEM ODM manufacturer in China.

factory introduction

Our factory operates a complete in-house production system, covering every key stage from mold making to final assembly.

With specialized workshops and advanced equipment, we ensure stable quality, flexible customization, and efficient mass production for global OEM/ODM projects.

Explore our core workshops below to see how your product is manufactured at each stage.

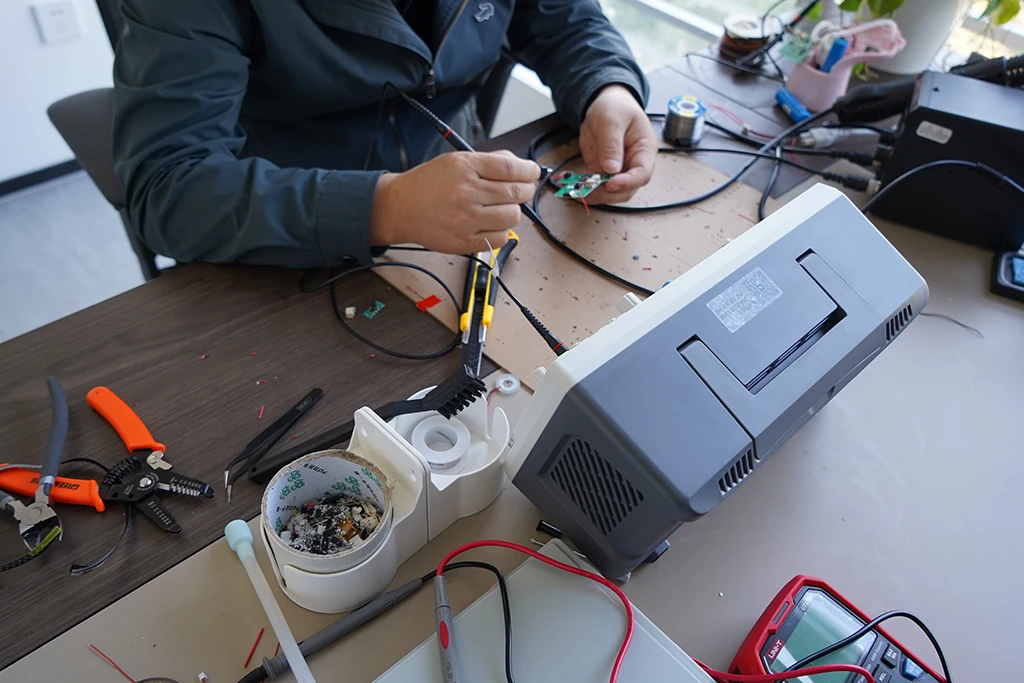

Mold Workshop

Our in-house mold workshop integrates mold design, CNC programming, and precision machining, enabling us to develop reliable molds for mass production.

Equipped with advanced CNC, EDM, wire cutting, and milling machines, we ensure high accuracy, stable structure, and long mold lifespan.

With a monthly capacity of 40 mold sets, we manufacture hard plastic molds, soft plastic molds, PVC casting molds, and silicone molds.

From product structure design to final mold delivery, all processes follow standardized operating procedures to guarantee consistent quality.

Why Our Mold Workshop Matters

In-house mold making reduces development time and cost

High-precision machining ensures stable mass production

Suitable for OEM/ODM projects with complex structures

Fully Automatic Mirror EDM Machine

CNC wire cutting machine

Automatic Steel Feeding System

High-Precision CNC Milling Machine

Gun Drill Machine for Deep Hole Processing

CNC Machining Workshop Overview

Injection molding workshop

Our injection molding workshop is equipped with over 30 advanced injection molding machines, featuring clamping forces from 128 to 368 tons, suitable for both small and large-size molds.

All machines are integrated with 5-axis automatic robotic arms, enabling stable, efficient, and fully automated production.

With a daily output of up to 43,000 pieces, we ensure consistent quality and reliable delivery for mass production projects.

Injection Molding Capabilities

Wide tonnage range for diverse product sizes

Automated production for high consistency

Ideal for OEM & ODM mass production

Donghua Injection Molding Machine

Donghua Injection Molding Machine

Jiaming Injection Molding Machine

Automated Injection Molding Line

Precision Injection Production Area

Automated Picking & Conveying System

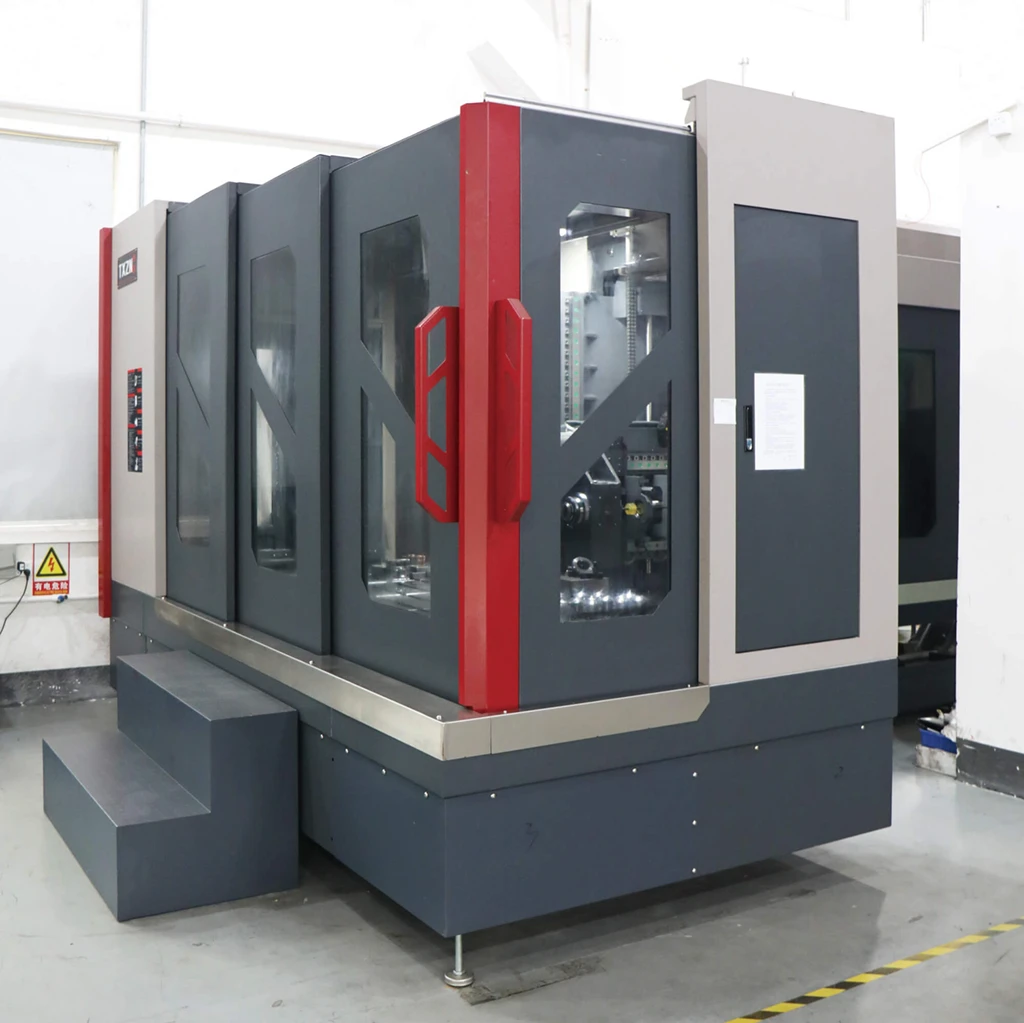

Silicone workshop and flocking workshop

Our silicone workshop is equipped with multiple silicone hydraulic molding machines and rubber mixing systems, supporting stable and repeatable high-temperature molding for complex silicone components.

The flocking workshop operates in a fully enclosed cleanroom environment and is equipped with electrostatic flocking machines, pre-treatment units, and curing lines, ensuring uniform texture, strong adhesion, and consistent surface quality.

This integrated setup allows us to deliver complete silicone and flocking solutions, from material preparation to final surface finishing, meeting both functional and aesthetic requirements.

High-temperature silicone molding

Cleanroom electrostatic flocking process

Stable surface finish & strong adhesion

Suitable for OEM & ODM customized products

Silicone Hydraulic Molding Machine

Silicone Production Area

Manual Silicone Trimming Area

Rubber mixing machine

electrostatic flocking machine

Flocking Drying & Curing System

Spray painting workshop

Our spray painting workshop integrates large-area spray painting, fine-detail spray painting, pad printing, and hand-applied painting, enabling flexible surface finishing for products of different sizes and design requirements.

Each process follows a standardized production workflow, with strict control over color accuracy, coating thickness, and surface consistency to ensure stable quality and high production efficiency.

This workshop is especially suitable for custom PVC figures and appearance-critical products, delivering vibrant colors, smooth finishes, and reliable mass production results.

Surface Finishing Capabilities

Large & small-area spray painting

High-precision pad printing

Manual detail painting for complex designs

Consistent color & surface quality control

Large-Area Spray Painting Booth

Precision Mini Spray Painting Line

Pad Printing Department

Hand Painting & Detail Finishing

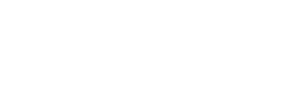

PCBA Workshop

Our PCBA workshop is equipped with advanced SMT production lines, including Yamaha pick-and-place machines, solder paste printing systems, reflow soldering equipment, and automated optical inspection (AOI).

From component placement to soldering and inspection, each step follows strict quality control standards to ensure stable performance, accurate assembly, and consistent reliability. Automated dip soldering is used for through-hole components, followed by detailed post-solder inspection and manual finishing.

This workshop supports ODM electronic gifts and small home appliances, delivering dependable PCBA solutions for both prototyping and mass production.

PCBA Capabilities

SMT & through-hole assembly

AOI inspection & quality control

Stable small-batch & mass production

ODM support for electronic gifts & appliances

Yamaha Pick-and-Place Machine

Solder Paste Printing System

Reflow Soldering Line

Automated Optical Inspection (AOI)

Automatic Dip Soldering Machine

Post-Solder Assembly Line

Assembly Workshop

Our assembly workshop operates 12 well-organized production lines, designed for efficient workflow and stable mass production. Each line follows standardized operating procedures, with clearly defined roles to ensure accuracy and consistency at every stage.

From component assembly to final packaging, products move through a controlled and streamlined process. This structured production system ensures high efficiency, reliable quality, and on-time delivery for both custom PVC figures and electronic products.

Assembly Capabilities

12 production lines

Standardized workflows

Manual & semi-automated assembly

Suitable for ODM mass production

Multi-Line Assembly Workshop

Standardized Assembly Line

Mass Production Assembly

Functional Testing & Assembly

Final Assembly & Inspection

Packaging Preparation

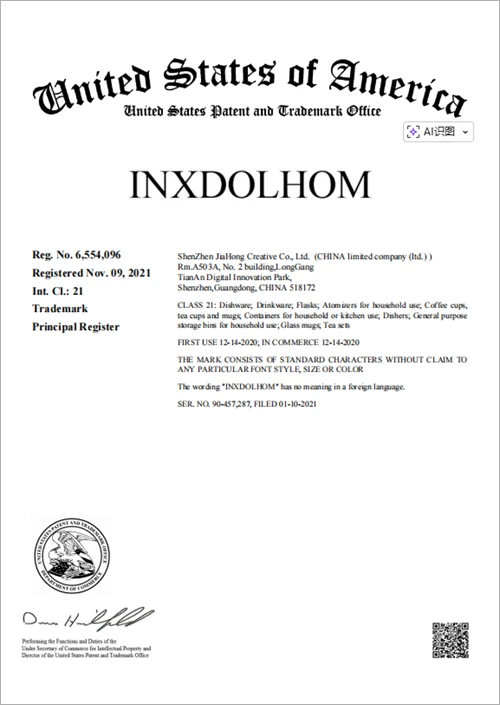

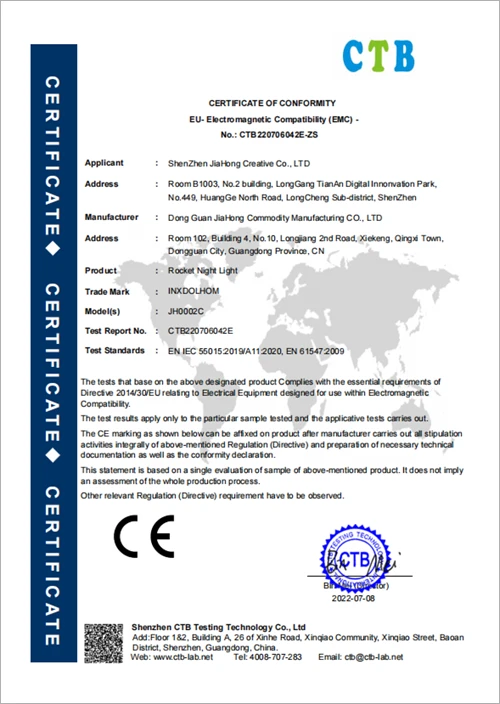

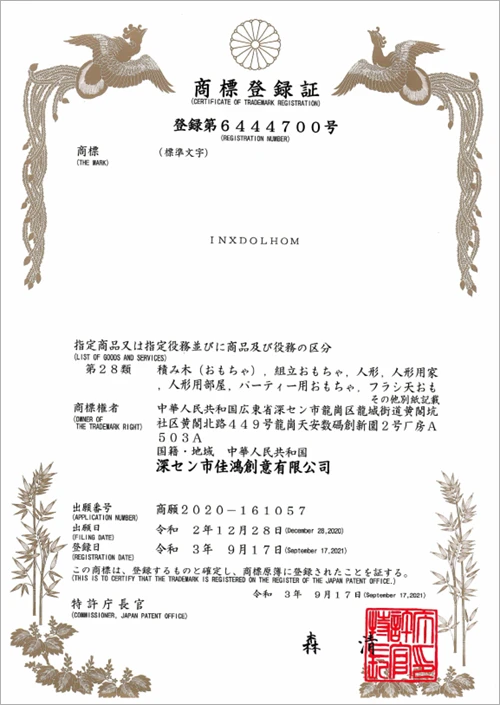

Certification

We comply with international safety and quality standards including CE, ASTM, RoHS, EN71-1/2/3, and FCC.

All products are manufactured using non-toxic, eco-friendly materials and are free from harmful substances such as phthalates. From raw materials to mass production, we implement strict quality control procedures to ensure consistent safety, reliability, and compliance.

Our PVC toys, figurines, and IP-authorized small home appliances meet the regulatory requirements of Europe, the United States, and other global markets, providing our clients with confidence for worldwide distribution.

Frequently Asked Questions About Jiahong Creative

Q: Are you a factory or a trading company?

A: We are a direct manufacturer with in-house R&D and production facilities,an OEM ODM manufacturer in China,not a trading company.

Jiahong Creative operates its own factory covering over 30,000㎡, with dedicated departments for mold making, injection molding, silicone, spray painting, PCBA, assembly, and packaging. This allows us to control quality, cost, and delivery timelines from prototype to mass production.

Q: What types of clients do you work with?

A: We primarily work with brands, IP licensors, distributors, and product development teams worldwide.

Whether you are launching a new IP product, expanding a homeware line, or developing custom promotional merchandise, we support OEM & ODM projects with flexible customization depth.

Q: What level of customization do you offer?

A: Our customization goes far beyond appearance. We offer full-process customization, including:

Industrial & structural design (2D / 3D)

Material selection (PVC, ABS, silicone, etc.)

In-house PCBA & electronic function customization

Prototyping, testing, and mass production

This means your product is truly proprietary, not a modified off-the-shelf item.

Q: How do you protect client designs and IP?

A: We take IP protection seriously. All projects can be protected under NDA agreements, and sensitive files are handled strictly within our internal teams.

Our long-term cooperation with global licensed brands has established standardized IP protection and compliance processes.

Q: What if this is my first time working with Jiahong Creative?

A: We recommend starting with a prototype or small trial order.

Our team will guide you through design validation, cost structure, and production planning step by step, ensuring transparency at every stage before mass production.

Inquiry Now

We support global brands with custom PVC figures and homeware products from design to mass production.

Your information is strictly confidential and used only for project evaluation.

About Us

Who We Are

We support custom PVC manufacturing and small home appliance projects from concept and prototyping to mass production.

How We Work

- Design review & feasibility analysis

- In-house mold making & sampling

- Stable mass production & quality control

Our manufacturing base covers 30,000㎡ with 700+ skilled workers, supporting consistent quality and lead times.

Who We Work With

We collaborate with brands, IP owners, studios, and distributors on long-term custom manufacturing projects.