Service

INXDOLHOM

Manufacturing Process Timeline

The production timeline for jiahong creative depends on the factory’s manufacturing schedule. The following production times are provided for reference only, as the actual timeline will be determined by the final circumstances. Uncontrollable factors or last-minute design changes may result in extended production durations.

3D Parts Disassembly

Analysis and separation of 3D model components for manufacturing

3D Printing & Prototyping

Rapid prototyping using 3D printing technology

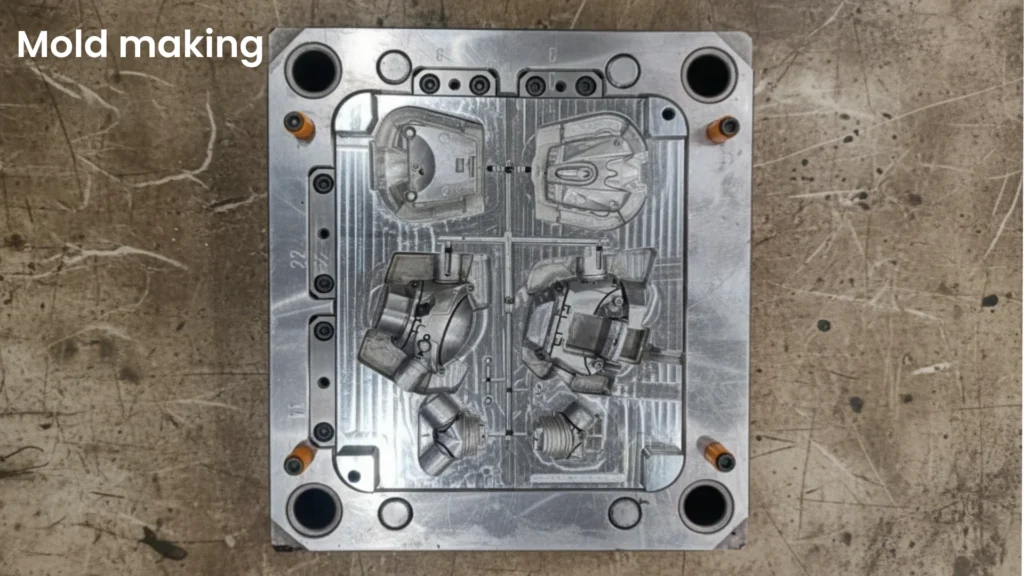

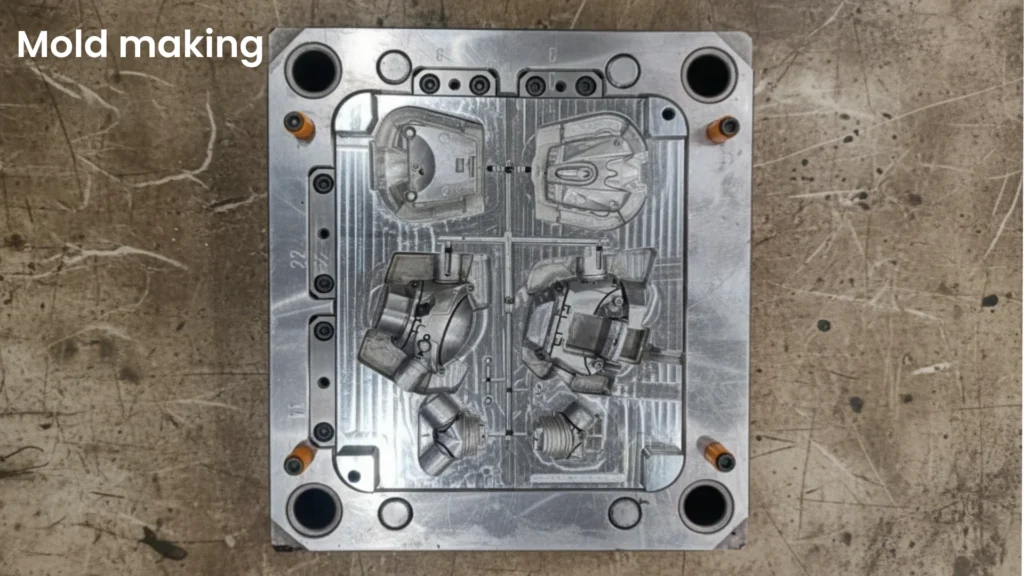

Mold Making

Creating production molds for mass manufacturing

Mass Production Sample

Creating sample products from production molds

Batch Production

Estimated: 30–45 days

(Based on 3,000 pcs. Timeline optimized according to order quantity & factory schedule)

3D Modeling from 2D

Creating 3D models from provided 2D drawings

3D Parts Disassembly

Analysis and separation of 3D model components for manufacturing

3D Printing & Prototyping

Rapid prototyping using 3D printing technology

Mold Making

Creating production molds for mass manufacturing

Mass Production Sample

Creating sample products from production molds

Batch Production

Estimated: 30–45 days

(Based on 3,000 pcs. Timeline optimized according to order quantity & factory schedule)

Production Process

Payment

Any business service requires payment, different industries the payment Items are different. our industry total have 6 links need to be paid, they are sample fee and sample freight, mold fee, mass production deposit & balance, bulk freight. The time and order of payment are as follows:

| ITEM | PAYMENT POLICY |

|---|---|

| Sample fee | 100% be paid before start |

| Smaple freight | be paid before shipping |

| Molds cost | 100% be paid before make molds |

| Pre-production sample freight | be paid before shipping (no shipping no need pay) |

| Advance payment for mass production | 40% deposit be paid before mass production |

| Final payment for bulk goods | 60% balance be paid before shipping |

| Freight of bulk goods | If need us help to arrange shipping services |

Note: These costs do not include additional charges for customized packaging, customs clearance fees, or other extra service fees. A detailed quotation for all requested services will be provided, and your approval will be obtained before Jiahong creative commences the services.

FAQ

Q1. Can you help if I only have an idea or sketch?

A: Yes. You don’t need a finished 3D file to start. Our in-house design and engineering team can support you from ideas, sketches, or reference images all the way to a production-ready prototype.

Q2. Do you support licensed IP product manufacturing?

A:Yes. We support authorized IP projects and work closely with licensors to ensure compliance with brand and quality standards.

Q3. What is the minimum order quantity (MOQ) for custom PVC figures?

A: MOQ varies based on size, structure, and production process. For most custom PVC figures, MOQ typically starts from 1,000–3,000 pcs. We evaluate each project individually to provide the most cost-effective solution.

Q4. Do you handle licensed or IP-authorized products?

A: Yes. We have extensive experience working with licensed IP projects. Clients are required to provide valid authorization documents before production. All IP-related projects are handled strictly according to licensing requirements.

Q5. How long does the full process take from design to mass production?

A: A typical project timeline includes:

• Design & prototyping

• Mold making

• Pre-production sample

• Mass production

The total lead time depends on design complexity and order quantity. A clear production schedule will be provided after project evaluation.

Q6. What are your payment terms and accepted payment methods?

A: We accept T/T (bank transfer). Standard payment terms are:

• Deposit before mold making

• Balance before shipment

Payment terms can be discussed based on project scale and cooperation stage.

Still have questions? Our team will review your project and provide a clear solution before any commitment.

Why Brands Choose Jiahong Creative

① End-to-End Custom Manufacturing

From concept, 3D design, prototyping, mold making to mass production — all processes are handled in-house, ensuring quality control, efficiency, and clear communication at every stage.

② Proven OEM / ODM Experience

With 15+ years of experience, we support global brands and licensors in custom PVC figures and licensed consumer products, delivering market-ready solutions with stable quality.

③ In-House Mold & Painting Workshops

Our dedicated mold-making and hand-painting workshops allow us to control details, timelines, and costs — reducing risks commonly faced when outsourcing critical processes.

④ Reliable Production & Delivery

With a factory covering 30,000㎡ and a skilled workforce of 700+ employees, we are equipped to handle medium to large-scale orders with consistent quality and on-time delivery.

⑤ Clear Communication & Project Support

Each project is managed by a dedicated team providing clear quotations, production updates, and photo/video feedback throughout the process — no hidden steps, no surprises.

From idea to finished product, Jiahong Creative is your reliable manufacturing partner in China.

Start Your Custom Project

service

How Custom Works

From idea to finished product — simple & clear.

Production Process

3-Step Process

Step 1 — Share Your Idea

Send us your sketch, reference images, or concept. No technical files required.

Step 2 — Design & Prototype

Our in-house team creates 3D designs, molds, and samples for your approval.

Step 3 — Mass Production

After confirmation, we move to stable production with quality control and global shipping.

What We Can Customize

- Custom PVC Figures

- OEM / ODM Electronic homgware

- Build your own brand product

Why Work With Us

We operate as a direct factory with in-house design, mold making, and production — ensuring quality, cost control, and reliable lead times.