OEM anime figure manufacturing is the industrial process of producing anime figures based on a client’s original design, IP, or concept, with the factory responsible for engineering, mold making, mass production, and quality control.

For brands, IP owners, and creators developing custom figure anime, OEM manufacturing is the only reliable path from concept to commercial-scale production.

What Does OEM Anime Figure Manufacturing Mean?

OEM anime figure manufacturing differs significantly from simple custom sampling.

In OEM projects:

- The client owns the character design and molds

- Figures are produced exclusively for one brand or IP

- The factory supports long-term, repeatable production

This model is essential for any custom figure anime project intended for retail, crowdfunding, or brand distribution.

OEM Anime Figure Manufacturing vs Trading Companies

Many buyers mistakenly work with trading companies when searching for OEM anime figures. The difference becomes clear once production begins.

| Aspect | Trading Company | OEM Anime Figure Factory |

|---|---|---|

| Design Engineering | Outsourced | In-house |

| Mold Control | Limited | Full control |

| Production Stability | Unstable | Consistent |

| Quality Management | Fragmented | Standardized |

| Scalability | Weak | Strong |

For custom figure anime mass production, factory-level OEM capability is critical.

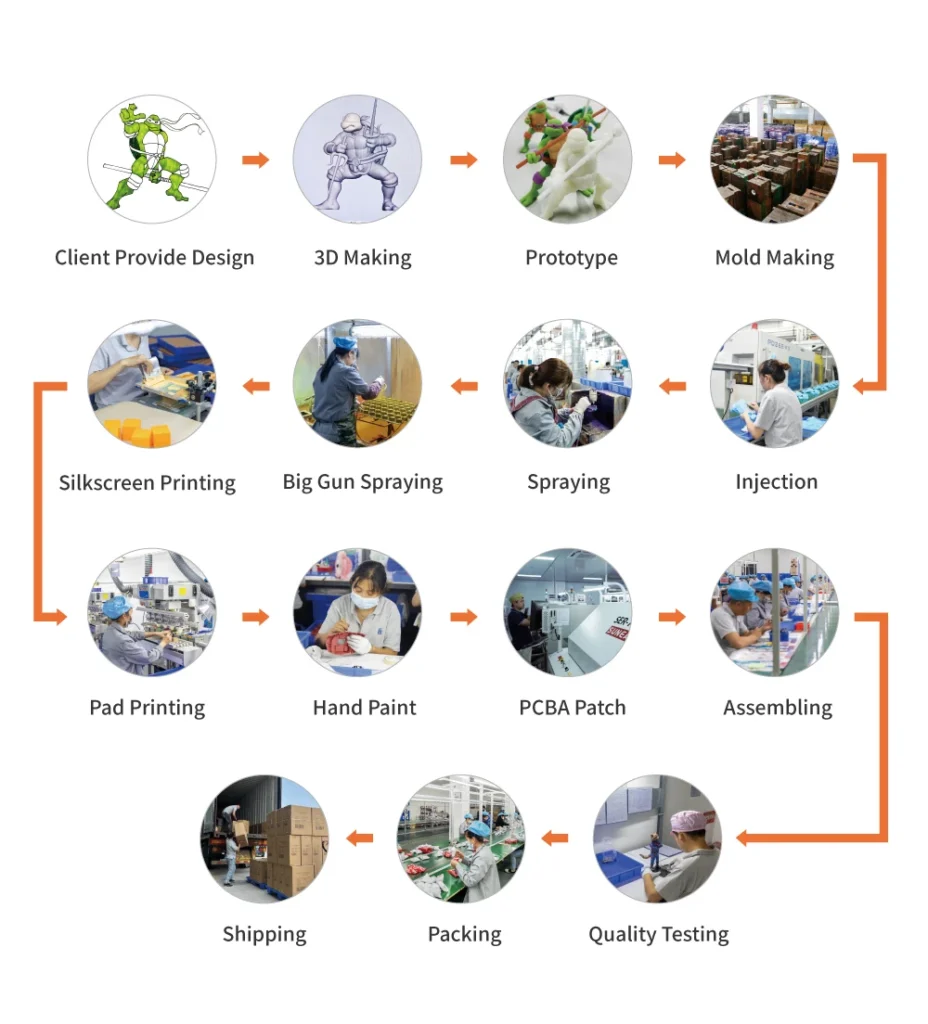

OEM Anime Figure Manufacturing Process Explained

A professional custom anime figure factory follows a structured OEM workflow designed for stability and scalability.

1. Design Evaluation & Engineering

2D artwork or references are reviewed and optimized for manufacturability, including pose balance, wall thickness, and part separation.

2. Production-Ready 3D Modeling

The factory creates 3D models that preserve anime aesthetics while meeting mold and PVC injection requirements.

3. Prototype Development

Physical samples are produced and refined to ensure the design can be replicated consistently.

4. Mold Making

High-precision molds are created to maintain facial detail, hair texture, and accessory accuracy across production batches.

5. Mass Production

PVC injection, trimming, assembly, painting, and finishing are conducted under standardized production lines.

6. Quality Control & Packaging

Each batch undergoes inspection to ensure consistency with the approved prototype before export packaging.

This process allows OEM anime figure manufacturing to support both small and large custom figure anime projects.

Why OEM Manufacturing Is Essential for Custom Figure Anime

Custom figure anime projects often fail when factories lack OEM experience. Common risks include:

- Mold deformation after limited runs

- Inconsistent paint application

- Structural instability in thin parts

OEM anime figure manufacturing eliminates these risks by controlling every stage internally.

Factories with design, mold making, and assembly under one roof provide higher reliability and lower long-term cost.

PVC Expertise in OEM Anime Figure Manufacturing

PVC is the most widely used material for custom anime figures, but improper handling can lead to deformation or color issues.

Professional OEM anime figure factories manage:

- PVC formulation

- Injection temperature and cooling

- Long-term color stability

This ensures custom figure anime products remain visually accurate during shipping and long-term display.

OEM Anime Figure Manufacturing for Different Project Scales

OEM manufacturing supports a wide range of custom figure anime needs:

- Low MOQ for independent creators

- Medium production runs for studios

- Large-scale orders for global brands

A factory with sufficient workforce and facilities can scale production without compromising quality.

OEM Manufacturing and Long-Term Brand Growth

OEM anime figure manufacturing allows brands to:

- Protect IP and mold ownership

- Maintain consistent product quality

- Build reliable supply chains

- Scale production efficiently

For commercial custom figure anime projects, OEM manufacturing is not optional—it is foundational.

Work with a Professional Custom Figure Anime Manufacturer

Choosing the right OEM partner determines whether a custom figure anime project can move beyond sampling and into stable production.

Learn more about working with a factory-level partner here:

Custom Figure Anime Manufacturer

visit our youtube website to learn more.

FAQ – OEM Anime Figure Manufacturing

Frequently Asked Questions

What is OEM anime figure manufacturing?

OEM anime figure manufacturing is a factory-based production model where anime figures are produced according to a client’s original design, with full control over engineering, molds, mass production, and quality control.

How is OEM anime figure manufacturing different from custom samples?

Custom samples focus on appearance, while OEM manufacturing ensures the figure can be mass-produced consistently with stable quality and controlled costs.

What materials are commonly used in OEM anime figures?

PVC is the most common material for OEM anime figures due to its flexibility and durability. ABS may be used for structural components, while resin is typically limited to prototypes.

Is OEM anime figure manufacturing suitable for small brands?

Yes. Many OEM anime figure factories support flexible MOQ options, allowing independent creators and small brands to launch custom figure anime projects.

Why is factory-level OEM important for custom figure anime?

Factory-level OEM ensures consistent quality, controlled mold ownership, reliable delivery, and scalable production—key factors for commercial success.